Optimizing Logistics Centres and Warehouses with CCTVs Surveillance

Over the years, the expanding usage of AI-powered video analytics has significantly changed and enhanced the operations of company logistics and its numerous processes across industries. Supply chain management, which is defined as the management of numerous operations that make up the production flow from start to finish till the finished product is delivered to the client, has become smarter thanks to AI-enabled video analytics technology. CCTV cameras stream is embedded with an AI-based system which then adds intelligence to these devices, allowing them to thoroughly analyse data, recognise any important or abnormal events occurring at any point in the supply chain, and issue automated alerts in real-time. These CCTVs vital insights reduce the chances of any mishaps, or even completely avert any unfavourable events, resulting in improved outcomes and, of course, efficient supply chain management. Let’s dig deep into this.

Improve Stock Management and Production

Video Analytics is becoming increasingly important for organisations to provide better inventory management. Damage, theft, and pilferage of commodities occur frequently, whether they are at the warehouse or in transit. To address these issues, CCTV cameras video analytics are being used, which can follow and detect suspicious activity quickly and efficiently, as well as send alerts to a server through the network. The supply chain managers are then able to take immediate action to ensure that the products are delivered on time. The more things that are moved and the higher the turnover rate, the more difficult it is to keep track of individual units and their condition. CCTV surveillance can be used to monitor produced goods and assisting warehouse managers in managing vast inventory.

When goods of various sizes must be stored with the greatest possible efficiency, Video analytics can assist in real-time recognition of arriving and exiting items according to size and format, allowing picking machines to sort them accordingly. The possibilities of CCTV surveillance technology will considerably improve warehouse and manufacturing facility storage optimization.

Book A Free Demo

Loading and Unloading

Loss Prevention Managers will easily and conveniently collect products that have been recorded at the door, using CCTV systems for managing and monitoring loading and unloading. This is one solution even the top 10 Logistics companies in India are looking for. The time of loading and emptying can be quickly and simply determined by entering the products ID numbers. High-resolution video material can be used to show if harm was made during these operations or if things were placed wrongly knowingly or unconsciously. Firms can also use video analytics to analyse truck utilisation patterns on a regular basis and obtain a view of loading/unloading activity data, load per cent capacity, and so on when things are transferred in bulk from one site to another by road. This allows supply chain managers to monitor their fleet’s overall productivity and make necessary modifications to enhance the efficiency of logistics and supply chain management.

Compliance with the Safety Rules:

The first step is to ensure that safety laws are followed, as many accidents are caused by negligence, inappropriate machine use, human mistake or trucks pass by at high speeds. Through the identification of hardhats, high visibility vests, shoes, and even specific belts, smart camera solutions can check whether personnel are wearing safety items.

In the event of an incident, they aid in early detection, which is crucial when response time is limited. Smart cameras with behaviour detection can help to automatically recognise accidents at an early stage, similar to how they can help avoid break-ins and theft. If a worker falls to the ground or is struck by a falling object, for example, the system recognises this as odd behaviour and quickly notifies it. This can also be done by using the JARVIS App where the app will be installed on the mobile phone of the driver. Driver’s phone will cover the stream and real-time alerts will be sent to the video walls of the logistic company.

Smoke and Fire Detection:

If smoke or fire is detected, an immediate notification is received on the video wall, phone, or e-mail. To ensure their joint functioning, the Smoke and Fire Detection alert can be integrated with a fire alarm or a fire extinguishing system. There’s no need to stare at video surveillance monitors all day. AI-enabled Video Analytics respond quickly to fire and smoke, preventing the spread of a fire by pinpointing the exact position and origin of the fire. People in danger zones can be notified quickly so that they can be evacuated from a logistic centre or warehouse. Thus, CCTV surveillance is capable of ensuring personnel survival and health, as well as minimising damage to property, items stored in the warehouse, and warehouse equipment.

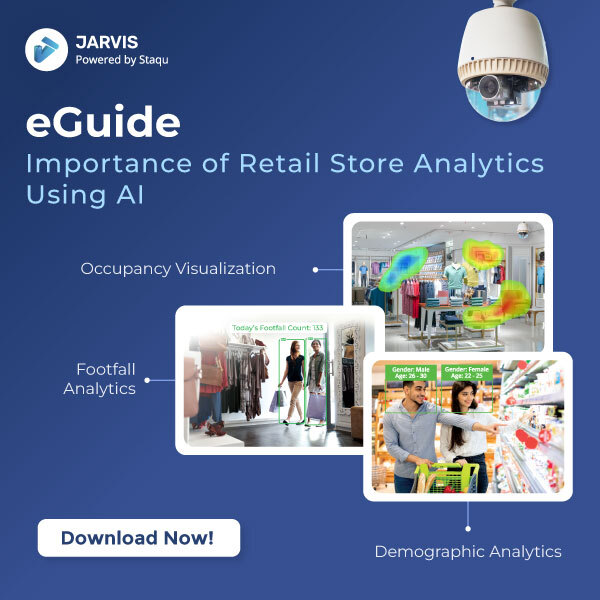

Download eguide

Efficient Entry and Exit Security

Video analytics can help warehouses and logistic service providers get the appropriate product to the right location and consumers in perfect condition that necessitates a secure and efficient supply chain. Smart ip cameras can help monitor the condition of packaging throughout the manufacturing and shipping processes, detecting open or damaged boxes and giving automatic identification of one of the key logistics concerns.

The price of an IP camera is not a challenge as the latest camera technology and advanced software algorithms can be deployed on the existing cameras. Footage directly from CCTVs is collected (edge-based processing), detecting a damaged shipment at the loading dock before it is accepted and put into a vehicle for delivery to the customer. Smart cameras at the facility level can also inform drivers with incoming shipments of empty loading bays for offloading or facility employees of potential bottlenecks or risks for inbound and outbound vehicles, which could cause delivery schedules to be delayed to the minute.

By recognising arriving and outgoing trucks, cameras equipped with licence plate recognition analytics (ANPR) can help with entrance and exit management playing a vital role in logistics in transportation. Manufacturing plants and warehouses can employ analytical insights for access control and security by ensuring that only authorised vehicles are allowed to enter.

Streamlining Package Tracking

Loading ramps, for example, are widely used as critical locations in the package tracking process. As a result, a complete video recording of a package’s journey from the packaging lane to the package conveyor to the freight forwarder’s handover is quite useful. It enables you to establish clarity in the event of any damage, warranty claims or missing merchandise. In the event of a disagreement, this allows you to easily manage customer claims and demonstrate that a product was not damaged when it left your logistics zone.

Personnel Monitoring

Employees’ work performance at the logistic centre and warehouse is recorded. The presence or absence of movement in the activity monitoring zone is tracked in real-time to mitigate the dangers associated with the human factor. Heatmap analysis can also be done using CCTV surveillance. If there is no motion for an extended length of time, the one pre-programmed real-time alarm is sent. This innovation in logistics aids in the proper management of time and quality of work evaluations, logistic centre optimization, warehouse incentive programmes, and work processes.

As a result, staff work performance improves, and the likelihood of unfavourable events arising due to a lack of workers in the workplace is decreased.

Inoperability Detection:

Video Analytics innovation in logistics like configuring camera defocusing, turning the camera away from a pre-defined view, long-time flaring of a camera, or overlapping of the camera view, helps to reduce the time that the video surveillance cameras of a logistic centre are inoperable. When any of the above control events occur, a real-time alert is provided so that functionality can be restored rapidly. As a result, the workers, commodities housed in the warehouse, and infrastructure are always safe.

Currently, when COVID-19 has caused turbulence for practically all enterprises, prompting them to practise and implement expanded safety measures, video analytics has played a pivotal role in ensuring that all necessary safety procedures are done to restrict the spread of infection. CCTV cameras with video analytics can closely monitor people’s movements, ensuring that social distance rules are properly adhered to and that face masks are worn at all times. In the event that any of these standards are broken, the system will automatically send out alerts, allowing necessary action to be taken.

Needless to say, technological advancements have paved the way for a plethora of intriguing business options. Video analytics has proven to be incredibly useful in guaranteeing safety, quality, punctuality, performance, and productivity for businesses, in addition to providing visibility and transparency. The system has been successful in enhancing supply chain efficiency by seamlessly integrating with existing video infrastructure, ultimately translating to better customer happiness and improved business revenues.