5 Ways Video Analytics Software can Enhance Safety and Security at Manufacturing Plant

The manufacturing sector has experienced great growth in recent years, and the ineffective human duty of regular monitoring and analysis has been replaced with smart video analytics software. Not only does real-time alerting save loss due to a delay in incident identification, such as fire or intrusion, but it also saves lives by identifying abnormalities, inadequacies, risks, or threats.

According to a report, with 9.7 fatalities on the job site for every 100,000 workers, the construction business continues to have the fourth-highest rate of job site fatalities of any industry. Workers who are not wearing safety gear, such as safety helmets or jackets, frequently sustain injuries. Assuring that safety measures are being followed in real-time with video analytics can help to prevent workplace dangers and safeguard employees’ safety. For manufacturing plants utilizing AI-based video analytics software, the tremendous desire for worker safety, the need for automation to increase productivity, and access to improved quality will be the primary concern. In order to monitor activity, employee safety, and commercial security, most manufacturing facilities already have a number of CCTV cameras in place. Between 20 and 100 cameras may be present on a factory floor, making it hard for humans to continuously check for anomalies. For incident investigation, these cameras are typically employed after the fact. Here, VMS (Video Management System) can be of assistance. The following are some ways that artificial intelligence in manufacturing using video analytics improves safety and security in the manufacturing sector.

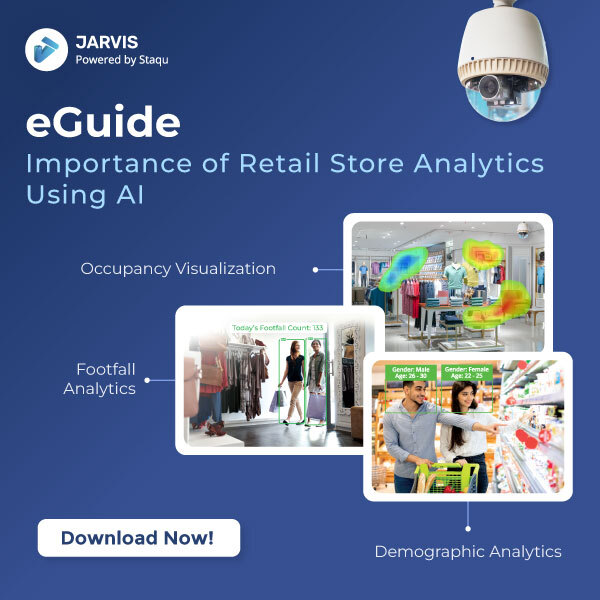

Download eguide

Also Read: How the leading-edge use of AI in manufacturing is changing the industry processes.

PPE Detection: Numerous studies show that workplace accidents result in significant indirect costs for businesses. Therefore, providing a safe workplace for employees is a fundamental responsibility of every organization. However, watching so many camera videos is frequently virtually impossible for managers to guarantee that every employee is donning PPE. Workplace injuries can be avoided by deploying video analytics because PPE can be identified and real-time alerts can be sent for visualization data which benefits an organization’s employees as well as its productivity.

Fire and Smoke Detection: Systems for detecting smoke and fire typically catch fire too late. For smoke to be detected and the alarm to sound with traditional systems, the fire must first reach a dangerous level. By that point, both safety and harm have been compromised.

Before it’s too late, an intelligent video analytics system aids in the early and accurate detection of flame and smoke. Real-time notifications improve site security by allowing for quicker responses. Even if all you detect is smoke, you’ll be able to locate the source, evaluate whether the threat is serious, and take appropriate action.

Person Collapsed Detection: People collapsing, slipping, tripping, and falling events that could have fatal consequences are among the incidents that video analytics software can identify. Supervisors can identify and remove fall hazards to create a safer work environment for their staff with the help of an automatic fall detection system.

Intrusion and Theft Detection- Security staff can be alerted as soon as an unwanted person or object enters factory premises with the use of improved video surveillance systems and AI-powered intrusion detection solutions linked to security infrastructure. Multiple camera feeds can be seen on a video wall, and an intrusion warning can be sent. Additionally, the gathered information is a reliable piece of proof when reporting theft or filing a theft insurance claim. Businesses utilize video analytics software to deter the theft of their goods and machinery. They can always keep an eye on their equipment by utilizing a video analytics service.

Book A Free Demo

Crowd Detection: Crowd detection is essential in manufacturing facilities. A quarrel or violent outburst may be indicated by an unusually large concentration of workers in one place. The sooner crowds are paid attention to (i.e., violent or destructive crowds are identified and reported), the less probable it is that there will be extensive harm or injuries. The number of workers in a specific area can be estimated in real-time using video analytic software, which also sets out an alarm to prevent any collisions.

Video analytics also offers operational intelligence like ANPR (Automatic Number Plate Recognition), smart conveying, loading/unloading time, and many others in addition to improving safety and security at manufacturing facilities. Drastically reduces the time to target security risks while boosting safety and streamlining operations by turning raw videos from cameras for CCTV into actionable intelligence. And there are just three simple steps involved in deploying video analytics software:

Because of the way factories work, physical security presents a number of difficulties at manufacturing facilities. These are sizable operations that operate in several shifts, stock products, and experience high employee inflow and outflow. Automation of safety and security measures may therefore be too much for management to handle. AI-powered video solutions can be very useful in real-world situations because all of this requires ongoing monitoring. With its JARVIS system, Staqu automates real-time alerts based on intelligent video analytics to address a variety of physical security issues, improve workplace safety and security, lower losses, and boost profitability.

Book a free demo for JARVIS today.